Services

Meai Technology

Services

The services of insert molding are below:

- Insert molding consulting

- New product development

- Existing products improvement

- Insert molding tooling and insert tooling design

- Insert molding product manufacturing

- Insert molding prototype development

- Insert molding product assembly

Insert molding consulting

We provide customers with comprehensive insert molding consulting services throughout the duration of their project partnerships, aiming to create innovative new products. Additionally, we collaborate closely with customers to identify and address technical and design challenges, enhancing existing products to reduce labor costs and streamline assembly time.

Insert molding

product development

When it comes to developing new products, our dedicated team is here to assist you every step of the way. We provide expert insert molding consulting to help you navigate the design and engineering process seamlessly. By collaborating closely with you, we ensure that your vision is accurately translated into optimized insert molding designs. Our experienced engineers employ advanced CAD/CAM software to create detailed 3D models, facilitating efficient review and approval.

Insert molding products improvement

We also offer valuable support in improving your existing products. Our insert molding consulting services extend to troubleshooting technical and design challenges to enhance product performance and efficiency.

Our skilled professionals work closely with you to identify areas of improvement, streamlining the manufacturing process to decrease labor costs and save assembly time. We employ innovative techniques and industry best practices to devise practical solutions tailored to your specific needs.

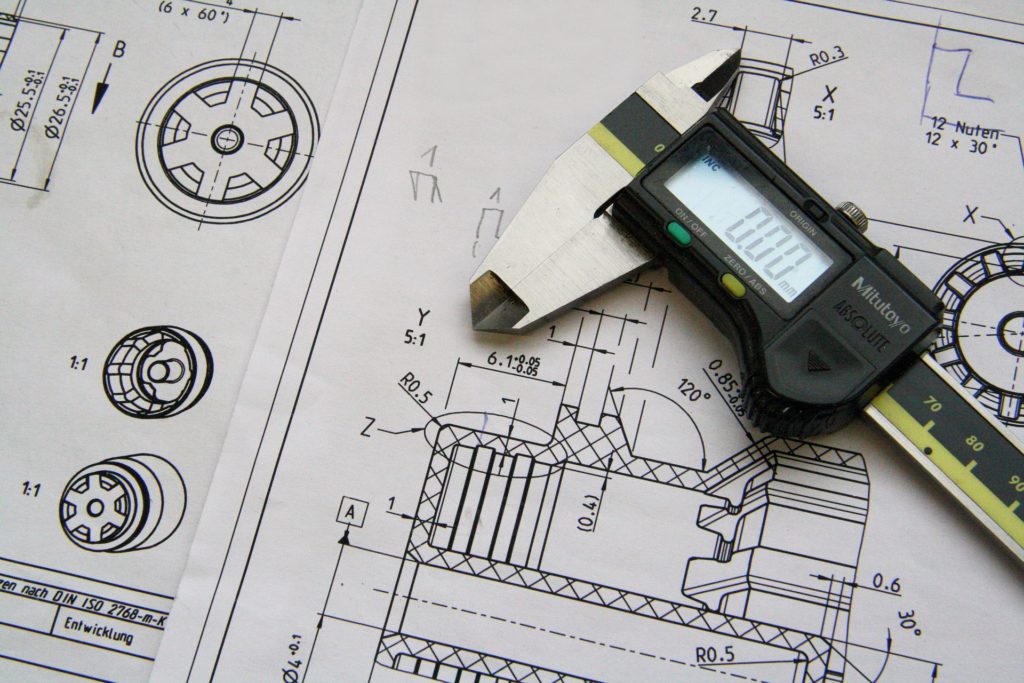

Insert molding tooling

and insert tooling design

By meticulously designing both the insert mold and plastic mold tooling for an insert molding product, we can effectively reconcile any conflicts between the two tools, ultimately achieving the best insert molding solution possible. Our team of experts will carefully analyze the requirements and specifications of your project to develop a harmonious integration of the insert mold and plastic mold, ensuring seamless functionality and optimal performance throughout the insert molding process. This comprehensive approach guarantees a successful outcome and maximizes the efficiency and effectiveness of your insert molding production.

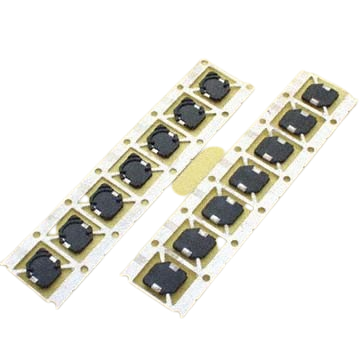

Insert Molding

Product Manufacturing

Our experienced team excels in insert molding manufacturing, utilizing state-of-the-art equipment and techniques to produce high-quality products. We work closely with you to understand your specifications and requirements, ensuring precise and consistent results. With our expertise in material selection, process optimization, and quality control, we deliver insert molded products that meet or exceed your expectations.

Insert Molding

Prototype Development

Prototyping is a crucial step in the product development process, allowing you to validate and refine your design before proceeding with mass production. Our team of engineers and technicians can assist you in creating functional insert molding prototypes. We utilize rapid prototyping techniques and cutting-edge technologies to quickly transform your ideas into tangible prototypes, enabling you to test and evaluate the product’s performance and make necessary adjustments before finalizing the design.

Assembly

In addition to manufacturing and prototyping, we offer comprehensive assembly services for insert molding products. Our skilled assembly team combines the molded parts with other components to create fully functional products. We follow precise assembly procedures and conduct thorough quality checks at each stage to ensure that the final assembled products meet your requirements and specifications.

Quality Assurance

Quality is our top priority. Throughout the manufacturing, prototyping, and assembly processes, we adhere to strict quality control standards. Our quality assurance team conducts rigorous inspections and testing to verify the integrity and functionality of the insert molded products. We are committed to delivering products of the highest quality and ensuring your satisfaction.

Collaborative Approach

We believe in collaboration and communication throughout the project. Our team will work closely with you to understand your specific requirements, offer technical expertise, and provide guidance at every stage of the manufacturing, prototyping, and assembly processes. We value your input and aim to exceed your expectations.

Contact us

If you’re in need of insert molding product consulting, manufacturing, prototyping, or assembly services, reach out to us today.

Our team is ready to discuss your project requirements, offer tailored solutions, and guide you through the process.